FIBCs

Experience the United Bags Advantage for FIBC (Bulk Bags, Super Sacks) and small bags across a multitude of industries.

- Manufacturing plants are audited by United Bags Quality Control Team.

- We are in partnership with the Customs Trade Partner Against Terrorism (C-TPAT) program.

- Bags are BRC, AIB, SQF, FSS 22000 and ISO 21898 certified with bags being produced meeting the Global Food Safety Initiative (GFSI) standards.

- Our quality control and experienced sales teams have the ability to test the safe working load of FIBCs in our innovation lab.

- Our Research & Development team can help you with your one-of-a kind designs.

- Our experienced sales team can manage your inventory (VMI) for just in time delivery with our advanced technology.

- We are UN and UL certified to ensure that your bags are meeting safety requirements.

Our innovation lab will test your current FIBC bag for FREE to ensure it meets quality standards.

- Are manufactured using plain woven polypropylene and other non-conductive fabrics

- Does not give static protection and should not be used with a combustible material

- Do not use near a flammable atmosphere

- Are made from materials that have a low breakdown voltage (less than 4KV) that halts propagating brush discharges (PBD)

- Although they can prevent PBD (propagating brush discharges), they are not considered anti-static bulk bags because they do not dispel an electrostatic charge

- They can be used in the presence of minor combustible dust with MIE more than 3mj, provided flammable vapors or gasses are absent

- The non-conductive polypropylene fabrics used to manufacture conductive Type C FIBCs are interwoven with conductive thread and sewn in a grid pattern

- The safe use of Type C bulk bags must be grounded throughout filling and discharge

- Flammable powders can be transported

- Can be used in the presence of flammable vapors, gases, dust, or solvents around the bag

- Sometimes called Antistatic FIBCs are inherently antistatic and do not require grounding to be safe

- The non-conductive polypropylene fabrics are interwoven with conducting threads and sewn in a grid pattern

- Bag does not need to be grounded

- Flammable powders can be transported

- Can be used in the presence of flammable vapors, gases, dust, or solvents around the bag

Circular

This style is made from fabric woven on a circular loom. The process eliminates the vertical seams on each side of the bag. The tubular body design is ideal to use without a liner and is ideal for fine products.

4-Panel

It requires seams along four separate pieces of fabric sewn together to create a 4-Panel bag. This style is excellent for a variety of applications.

U-Panel

This style takes two pieces of woven polypropylene material which forms the U shape. This is a cost-effective bag as it results in less stitching and waste. It is ideal for construction and a variety of industries.

Four Point

Cross Corner

Double Loops

Stevedore Strap

Tunnel Loops

Spout

Size can be altered by your filling equipment. The industry standard is 14” diameter x 18” length

Duffle

Opening as wide as the bag’s width and depth and acts as an extension of the bag.

Open

No closing material at the top of the bag

Spout

Size can be altered by your customers’ equipment. The industry standard is 14” diameter x 18” length. Covers can be added for increased protection.

Flat Bottom

Material is released by cutting the bottom panel

Full Bottom Discharge

The bottom panel of the bag is tied to the side to allow product to be released

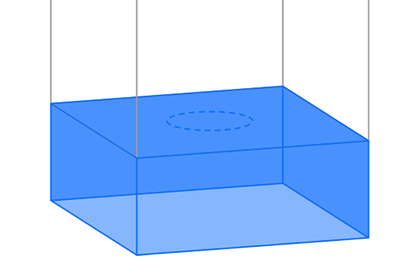

Porthole

The liner inside the bag is cut to allow the product to be released

Liners help keep the product safe by shielding it from moisture and oxygen and are used for safe transit of food products or fine powders. Eliminates the danger of products getting damaged by preventing contamination and prevents leakage from microscopic holes.

Liner Features

- Low or High-Density Polyethylene

- Can be loosely inserted in bags or attached with tabbing, which allows the liners to be sewed, tied, or glued to the bag, removing the chance of liner discharge

- Can provide anti-static properties

Liner Styles

Tubular Lay-Flat

- Cylindrical in shape with no spouts

- Open at the top, sealed at the bottom

Form Fit

- Made to fit the exact FIBC specification to reduce filling time by 30-35%

- Provides easier filling and discharge of the product

- Can heat-seal the top and bottom discharge spouts to keep product protected

- Holds 15-20% more material than the tubular liner

Specialty Liners

Baffled Liner

- Maintains the “cubic” form of the bag, improving storage and reducing bulging

Aluminum Foil Liner

- Offers superior protection against oxygen, moisture, and UV light and eliminates product odor

- Enhances filling, discharging, and handling of product by form fitting to the FIBC

Conductive Liners

- Vital for safe transportation of materials susceptible to static build-up

- The three types of conductive FIBC liners are: L1, L2, L3

We follow strict guidelines to produce food-grade bags, including on-site audits by the United Bags Quality Control Team.

Certifications: AIB, BRC, GMP, HACCP, ISO 9001

Raw Material: 100% virgin raw material and FDA approved lubricants for direct food contact

Fabric Cutting: Ultrasonic cutting to prevent any loose threads

Stitching: Sewn externally with twisted PP fibrillated yarn and seams, eliminating the chance of any loose filament or threads inside the bag

Inspection: Each bag is passed through a metal detector and inspected over lighted tables and vacuumed

Traceability: Ability to identify and track as it moves from raw goods to finished product

Packing: Shrink wrapped and covered to prevent contamination on a heat treated wooden or plastic pallet

To help improve a bags squareness, appearance, and stability of the load. It also utilizes storage or shipping space more efficiently. Baffle bags can also hold more volume and have less stretch than a standard FIBC.

Standard Baffle: Has pieces of fabric sewn across each corner of a tubular or 4-Panel bag to maintain the cubic form of the bag, reducing bulging

Net Baffle: Has mesh sewn across each corner of a tubular or 4-Panel bag to equal distribution of fill product and faster filling process than a standard baffle bag

They are designed to meet the requirements by the United Nations for transporting and storing hazardous materials. There are seven primary tests conducted as part of the certification process.

Types: 13H1, 13H2, 13H3, 13H4

Durability: Manufactured at a 6:1 Safety Factor

Certification: Our experienced sales team are certified to help you design your UN bags

MAP FIBCs can help to save food and improve sustainability. It works by applying a deep vacuum to the 100% airtight high barrier liners within the external FIBC. After this, the bags are gas flushed with either nitrogen or carbon dioxide. This results in residual oxygen levels inside of the liners being <1% and an inert atmosphere.

This method is the perfect solution for protection and storage for products such as food powders, nuts, dehydrated fruit, pharmaceutical powders (API), grain, coffee, rice, tea, chemical powders, pigments and many other products.

THE SIX KEYS THAT MAKE UP THE MODIFIED ATMOSPHERE APPLICATION SYSTEM

1. Liner Material

The liner in a FIBC depends on the product and circumstances during storage and transport. The liner is built with up to nine different layers of various materials, to create a barrier against moisture and keep ultra-low oxygen levels and the flavor intact. The liners are produced to very stringent quality conditions and up to ISO standards.

We use a wide range of barrier foils for moisture levels, oxygen and flavor for our liners such as conductive, aluminum, anti-static, dissipative, metalized OPP, EVOH and PA liners.

2. MA Powerqube & Powertube Liners

A FIBC with a form stabilized liner system inside ensures a square and optimal shape after filling, during storage and transport. The pre-shaped liner is completely welded in the top and bottom and if required in the side seams.

- 15% on transport volumes can be saved with form stable FIBC Liners.

- 15-20% less material used for the production of a liner

- Modular produced

- Unique controlled sealing technique

- High load ability

- ISO production facility

3. Valve (including filter)

The valve is attached to the liner of the FIBC and gives a secure airtight connection between the environment inside the bag and the Vacuum and Gas Injection Machine. Each valve is equipped with a filter, which ensures that products stay in the liner and gasses can move openly in and out of the liner.

A reliable valve is the key to a successful preservation process. The benefits are:

- Fool-proof connection

- Fast processing times

- Single or multiple flushes

- Lower energy needed

4. Automatic Spout Sealer

A machine that seals the filling spout of a FIBC so that the product content is secured. Depending on the size and position of the FIBC, the machine can be adjusted to its correct height and width of the filling spout. After positioning the filling spout into the sealing machine, the sealing process is fully automatic.

- Reliable and safe way of sealing

- Constant quality and performance

- Mobile moveable machine

- Small footprint and setup

5. Vacuum & Gas Injection Machine

Modified Atmosphere is used as a way of natural fumigation, using ultra-low oxygen levels (ULO) in combination with Nitrogen or Carbon Dioxide to protect products from infestation by insects and extending the shelf life of your products.

- Vacuum & gas flushing including pressure control & leak test

- Short process times

- Completely customizable process

- Highest class approved machine

6. Modified Atmosphere Control

There are two different ways to measure and control the Oxygen level inside the bags.

- The traditional and very reliable way to measure oxygen and gas levels is the evasive method which uses a needle tool that pierces into the sealed liner bag.

- The new way is a totally non-invasive technique called Sensor Spot Technology that does not require piercing a needle into the liner bag.

UNITED BAGS CAN PERFORM A TEST ON YOUR PRODUCT WITH OUR PORTABLE EQUIPMENT

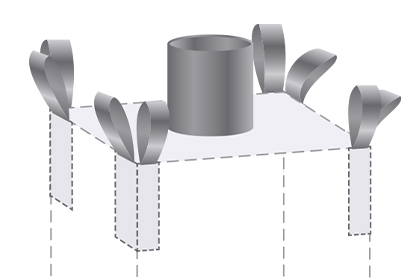

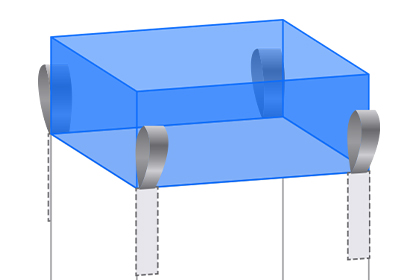

TELLAP pallet-less FIBC bags provide users with a low-cost alternative to a FIBC bag and wooden pallet. The TELLAP bag has two sleeves integrated into the base that holds the bag open for standard forklift tines. The sleeves allow a forklift to safely raise the bag from the base, eliminating the need for a pallet. Removing the pallet allows bag volume to be increased, lowering both operational and transport costs. Increasing the volume in each bag can lower transport costs per metric ton by up to 10%. That’s 10% fewer bags, containers, trucks, and forklift movements — the savings add up across many aspects of your business.

TELLAP pallet-less FIBC bags provide users with a low-cost alternative to a FIBC bag and wooden pallet. The TELLAP bag has two sleeves integrated into the base that holds the bag open for standard forklift tines. The sleeves allow a forklift to safely raise the bag from the base, eliminating the need for a pallet. Removing the pallet allows bag volume to be increased, lowering both operational and transport costs. Increasing the volume in each bag can lower transport costs per metric ton by up to 10%. That’s 10% fewer bags, containers, trucks, and forklift movements — the savings add up across many aspects of your business.

Product Features & Advantages:

- No pallet required. You can eliminate expenses for the fumigation, heat treating, storage, exchange, and disposal of wooden pallets.

- Bag and TELLAP sleeve made from 100% polypropylene and recyclable

- Bags can be safely stacked, reducing warehouse space requirements

- Increased payload means reduced operational and transport costs as sleeves weigh only 5 lbs (pallets weigh up to 65 lbs)

- No damage or contamination from nails, splinters, or foreign objects

- Sleeves are built into bags and tine guards slide into the sleeves

- Excellent stability and versatile

Biodegradable Materials:

FIBCs made from biodegradable materials, such as bioplastics or natural fibers, can break down naturally in the environment and reduce the amount of waste that ends up in landfills or the environment. These materials are made from renewable resources and have a lower carbon footprint compared to traditional plastic.

Reduced Packaging:

Companies can consider reducing the amount of packaging used in FIBCs by using lighter fabrics, reducing the size of the bags, or optimizing the shape of the bags to fit the product more efficiently. This reduces the amount of material used and can also reduce transportation costs and carbon emissions.

Reusability:

FIBCs can be designed for multiple uses, reducing waste and the need for frequent replacements. By using durable and high-quality materials, FIBCs can be reused multiple times, reducing the environmental impact of the packaging.

Environmental Impact Reduction:

rPET FIBCs are made from recycled polyethylene terephthalate, which is a plastic commonly used in water and soda bottles. By using rPET FIBCs, companies can help reduce the amount of plastic waste in landfills and the environment. This can have a positive impact on the environment by reducing greenhouse gas emissions and conserving natural resources.

Energy Conservation:

The production of rPET FIBCs requires less energy compared to the production of FIBCs made from virgin materials. Using more recycled materials means less virgin materials, less energy, and a smaller carbon footprint.

A Flexible Intermediate Bulk Container (FIBC) is a bag made out of woven polypropylene used to store and/or transport dry products. Dimensions can vary and typically hold anywhere from 2,000–4,000 lbs. Once the bags are filled, they are placed on pallets and forklifts use the corner lift loops to transport.

Bulk Bags, Big Bags, Super Sacks, and Totes

100% virgin polypropylene or up to 30% recycled polypropylene for sustainability. FIBCs can also be made from 100% recycled polyethylene terephthalate (rPET).

FIBCs come in many different sizes and styles and are customized for your product and are designed to fit squarely on a pallet.

FIBCs can be lifted with a forklift by either their loops or on a pallet.

You would need to lift the FIBC under a discharge area and open the discharge spout and let gravity do the work.

You will need:

- Bulk density of your product

- Type of filling equipment you will be using

- How much weight you plan to put in it

- The end users discharge equipment they will be using

A food-grade bag’s fabric is FDA approved for use in food packaging. Special steps are taken during the manufacturing process to ensure its safety, such as AIB, BRC, ISO, and SQF certifications.

Circular

- This style is made from fabric woven on a circular loom. The process eliminates the vertical seams on each side of the bag. The tubular body design is ideal to use without a liner and is ideal for fine products.

4-Panel

- It requires seams along four separate pieces of fabric sewn together to create a 4-Panel bag. This style is excellent for a variety of applications.

U-Panel

- This style takes two pieces of woven polypropylene material which forms the U shape. This is a cost-effective bag as it results in less stitching and waste. It is ideal for construction and a variety of industries.

Type A

- Are manufactured using plain woven polypropylene and other non-conductive fabrics

- Does not give static protection and should not be used with a combustible material

- Do not use near a flammable atmosphere

Type B

- Are made from materials that have a low breakdown voltage (less than 4KV) that halts propagating brush discharges (PBD).

- Although they can prevent PBD (propagating brush discharges), they are not considered anti-static bulk bags because they do not dispel an electrostatic charge.

- They can be used in the presence of minor combustible dust with MIE more than 3mj, provided flammable vapors or gasses are absent.

Type C

- The non-conductive polypropylene fabrics used to manufacture conductive Type C FIBCs are interwoven with conductive thread and sewn in a grid pattern

- The safe use of Type C bulk bags must be grounded throughout filling and discharge

- Flammable powders can be transported

- Can be used in the presence of flammable vapors, gasses, dust, or solvents around the bag

Type D

- Sometimes called Antistatic FIBCs are inherently antistatic and do not require grounding to be safe

- The non-conductive polypropylene fabrics are interwoven with conducting threads and sewn in a grid pattern

- Bag does not need to be grounded

- Flammable powders can be transported

- Can be used in the presence of flammable vapors, gasses, dust, or solvents around the bag

FIBCs can be used more than once if you have a multi-trip bag with a 6:1 Safety Factor (SF).

Discover Trusted Bulk Packaging Solutions with United Bags

United Bags is your premier partner for high-quality, customizable bulk packaging solutions. Our commitment to excellence and customer satisfaction ensures that you receive the best products tailored to your specific needs. Whether you're looking for durable, efficient, or eco-friendly options, our diverse range of products and services cater to various industries. Connect with us to explore our offerings and elevate your custom packaging with one of our experienced sales team members!